3D Food printing: What options the new technology offers

DLG Expert report 4-2017

Author:

- Sebastian Vogt, M.Sc. nutrition economics, Frankfurt am Main, Sebastian.Vogt@ernaehrung.uni-giessen.de

Contact:

- Dr. Annette Schmelzle, DLG Competence Center Food, A.Schmelzle@DLG.org

Introduction

We walk into the restaurant. The modern atmosphere is reflected in a unique and almost futuristic interior design. A digital menu on the table shows us the various dishes in a picture gallery, providing the most important information at a glance. With just a click we can obtain further details about the ingredients used and also learn something about the local producers. As a starter we choose small cubes of dough in geometrical perfection, from the middle of which dainty plants and mushrooms sprout. Our main course consists of traditional pasta in the form of beautiful rose blossoms with a classic tomato sauce. The idea of the rose-blossom pasta is mine. Before our holiday I found a digital 3D model on the Internet and emailed it to the restaurant. My beloved was amazed and absolutely thrilled – my surprise was thus evidently a great success. As a dessert we ordered a miniature copy of the Coliseum of Rome in chocolate – after all, we are spending our holiday in the Holy City. When we leave, the restaurant owner gives us a little present – a fruit gum message with the fragrance of Calabrian bergamot. It tells us once again “Grazie Mille” for our visit.

This is how reports of restaurant experiences might read in the future, when both parts of the inventory and individual dishes or complete menus come out of the 3D printer. The elements of this scenario can be realised in practice already today.

The opening of the first 3D printing restaurant in London in July 2016 made it possible to show the holistic implementation of such a concept. The event catering sector can already look forward to further developments in the coming years. The concept was presented at the 3D Food Printing Conference in Venlo in April 2016, when scientists, founders of start-ups and interested parties met in the Netherlands for the second time to discuss future possible applications of 3D food printing in business, the catering trade and private households.

Scientific research papers on 3D food printing have been available already for around ten years. Publications to date have focused on the selection of suitable foods and on optimisation measures to achieve greater stability in further processing steps (Lipton et al., 2015; Soares & Forkes, 2014; Gong et al., 2014; Southerland et al., 2011; Lipton et al., 2010; Cohen et al., 2009; Periard et al., 2007). More recent research work has addressed personalised 3D food printing on the basis of biometric data (Lipton et al., 2015) and the effects of 3D food printer use on suppliers and traders in the stationary retail trade (Jia et al., 2016).

From the 3D model to the printed food

3D food printing originated in industrial manufacturing. The first additive production methods were developed already in the 1980s, for instance by Charles Hull (stereolithography) and Scott Crump (Fused-Deposition-Modeling). The principle of the various production methods is, however, the same. Objects are modelled digitally on a computer and then produced layer by layer with a 3D printer. By contrast with subtractive production methods, such as milling or grinding, in additive production technologies no material is removed from the original workpiece. Accordingly only as much material as is actually required is used to build up items layer by layer.

ASTM International has defi ned the designation “Additive Manufacturing” as the overall term for additive production methods in international language usage. However, in everyday language the term 3D printing is frequently used.

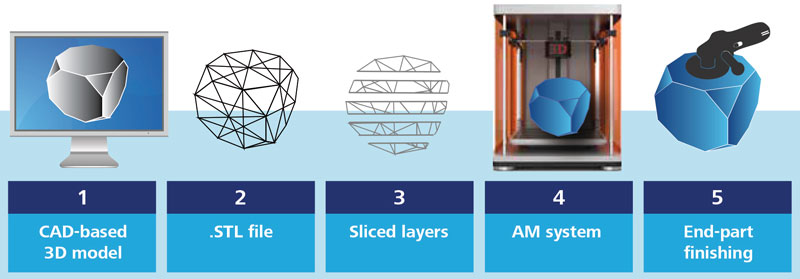

From the digital 3D model via the layered structure to the fi nished object – the same process steps are carried out in 3D food printing as in industrial 3D printing (Figure 1).

The essential difference is thus simply the use of foodstuffs as source material for the 3D printing operation. The properties of the selected foods can be altered as regards their form, colour, texture and taste in order to create new and individual products. First of all a 3D model is designed on the computer with a CAD program. The 3D model is then exported to the .stl (Standard Triangulation Language) fi le format. Here the original CAD model consisting of dots is covered with a surface (triangulation). In the next step the 3D model is dismantled into the individual print layers and the required printing parameters are defi ned. The “G-code fi le” containing all relevant information about the object to be printed is transferred to the printer. With the transfer of information from the G-code fi le, the 3D printer receives its orders such as, for example, output pressure, output quantity, movement coordinates and movement speed of the print head. The production method used for both industrial 3D printing and 3D food printing depends on the nature of the source materials.

According to Lipton et al. (2015), it is possible to distinguish between three approaches to 3D food printing. The “bio-driven” approach describes the artifi cial breeding of complex cell tissue with subsequent growth. While in the medical world “tissue engineering” is seen as a possibility for producing cartilage, vessels or organs artifi cially in a test tube in future, in the agricultural and food industry this technology is to serve as a resource-conserving and animal-friendly solution in meat production. Scientists at the University of Maastricht showed that such an idea is feasible already in 2013, with a burger bred in the laboratory. The “bottom-up” approach pursues the goal of making visually attractive and tasty foods from alternative food sources such as algae and insects. One example of this is the project “Insects Au Gratin” from Soares & Forkes (2014). Insects ground to powder are combined with chocolate or fresh cheese and seasonings such as ginger, cinnamon and dried chillies and then processed to new forms with the aid of a 3D printer. The goal of the project is to show the potential of insects as an alternative source of nutrients and protein, and as a contribution to worldwide food security. At present, however, the top-down approach is most frequently pursued and is therefore the most highly developed. Here, for instance, new forms and fi gures are produced from chocolate, fruit gum, pasta dough or sugar. By adding hydrocolloids to maintain the form, fruits and vegetables in purée form can also be printed.

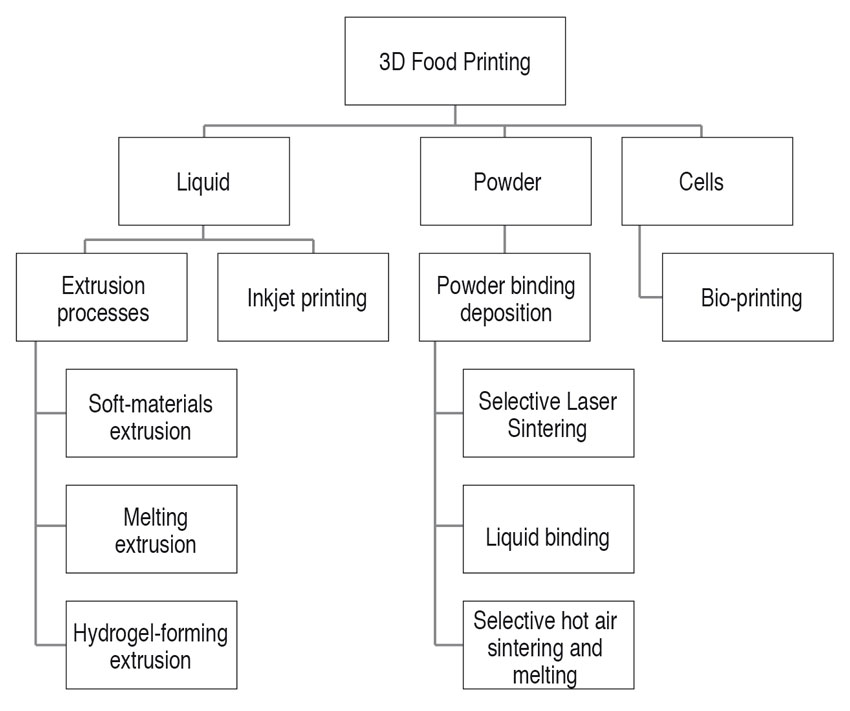

Godoi et al. (2016) classify the printing methods in 3D food printing on the basis of the nature of the source material (Figure 2).

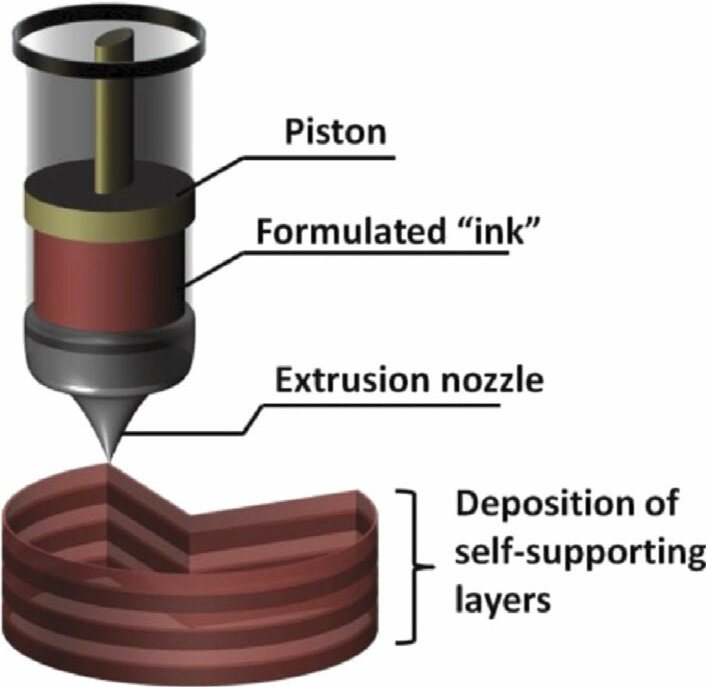

The extrusion-based methods and the methods based on pulverized foods are described here by way of example. Liquid or soft foods such as melted chocolate, fondant, pasta dough, as well as fruit and vegetable purées are used in the various extrusion methods. The mass is fi rst fi lled into a cartridge and then squeezed under pressure through an extrusion nozzle (Figure 3). Due to its physical properties, melted chocolate can be processed very well and is currently one of the foods used most frequently in 3D food printing. The selection and nature of the foodstuffs ultimately determine the dimensional and form stability. Accordingly the printed objects can maintain their form due either to their rheological properties, the subsequent cooling phase, or the additional use of a hydrogel. The parameters defi ned in advance, such as output pressure, output quantity, movement coordinates and movement speed of the print head also substantially infl uence the form stability.

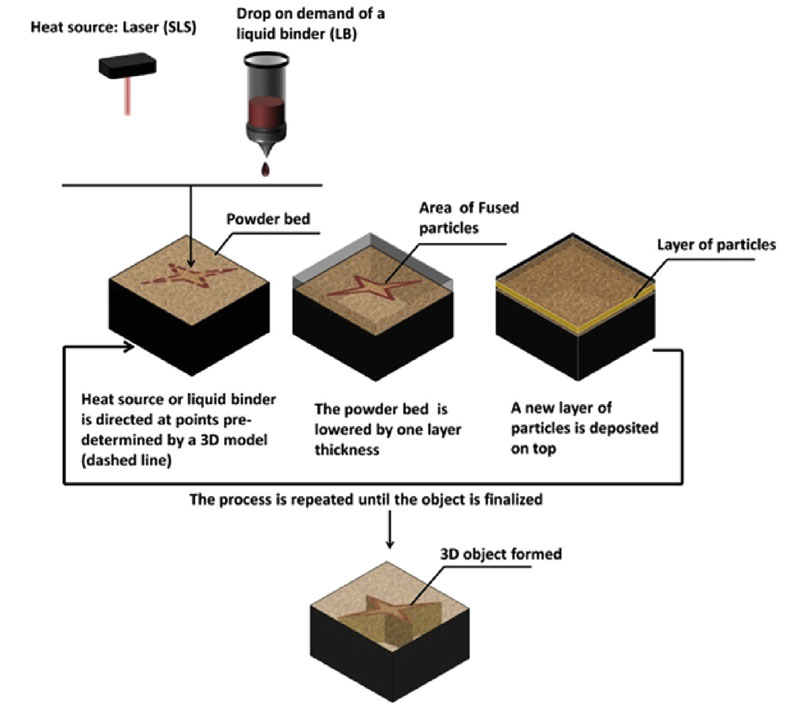

In the case of powder-based methods, for example sugar, cocoa powder or seasonings are used to create more complex forms. The source material is fi rst spread over a level surface which can be lowered. A heat source such as a laser or a hotair current serves to heat the particles of each layer along the coordinates briefl y and thus melt them together at the appropriate places. The building platform is lowered by one layer thickness and a new set of powder material is then spread over the surface and again melted together at the predefi ned places (Figure 4). Alternatively a liquid bonding agent can be used for this operation (Figure 4).

Possible uses in practice

Interest in 3D food printing is high, not only in scientifi c research. Although the possible applications are still very limited at present, companies are already experimenting with the new technology and at the same time are searching for new fi elds of business. From use in private households, via (high-end) gastronomy and catering for the elderly, to use in future spacefl ight missions – the possibilities appear unlimited. A few start-ups, companies and projects in which 3D food printing plays a central role are presented below.

Print2Taste, a German start-up from Freising, has been working since 2014 on developing a 3D food printer, the Bocusini. The finance for the project was realised within a few days via a crowd-funding campaign. The start-up made the headlines for instance in September 2015 – at the international trade fair for bakers, confectioners and snacks, the Bocusini printed a model of Neuschwanstein Castle from 500 g marzipan in eight hours. The company reports that the Bocusini is able to process more than 30 different foods. Alongside marzipan these include fondant,purées, fresh cheese and yoghurt. In October 2016 Print2Taste presented a further development of the Bocusini with which it is possible to scan persons in three dimensions and reproduce them in marzipan. At a net price of EUR 2,485 (as at February 2017), it is to be assumed that the main users of this system will be professionals. Natural Machines, a start-up based in Barcelona, is also developing a 3D food printer for professional use – the Foodini. Further development is then envisaged to cover possible applications in private households.

Not only start-ups but also well-known companies in the food industry are already intensively looking into the possibilities of 3D food printing. One of these companies is the confectionery manufacturer Katjes. In August 2015 the company presented the first food-certified 3D fruit gum printer for the retail trade – the Magic Candy Factory. Since then customers in the Katjes Café Grün-Ohr in Berlin have been able to have individual fruit gums from a selection of various forms and flavours printed within a few minutes. As an alternative, the Magic Candy Factory is able to print personal fruit gum greetings on edible paper. Since 2016 Katjes has been on an expansion track with further development of the Magic Candy Factory. Across the world the potential customers include traditional sweetshops, leisure parks and department stores.

The Italian Barilla Group has focused on a gastronomic application with its development of a 3D pasta printer. The machine was presented at the EXPO 2015 in Milan and is to be used in future for producing individual pasta shapes. Guests will be able to select shapes from a variety of new creations via a tablet computer. Heart-shaped pasta for the first date, or pasta in the form of a rose for anniversaries are just a few examples. It is also conceivable that guests can bring along their own pasta shapes based on 3D models stored on a USB stick, or send these to the restaurant in advance by email with the table reservation. The combination of alternative basic ingredients aims not only to ensure new taste experiences for the guests, but also to help individualise foods, and this will benefi t in particular persons with food intolerances. One crucial disadvantage currently lies in the printing speed. The 3D pasta printer needs about two minutes for four individual pasta shapes and is thus unsuitable for use in the catering industry. Despite this the company sees great potential for the future of the technology and launched a design competition for the second time in December 2016 in which participants were invited to submit new and creative pasta shapes.

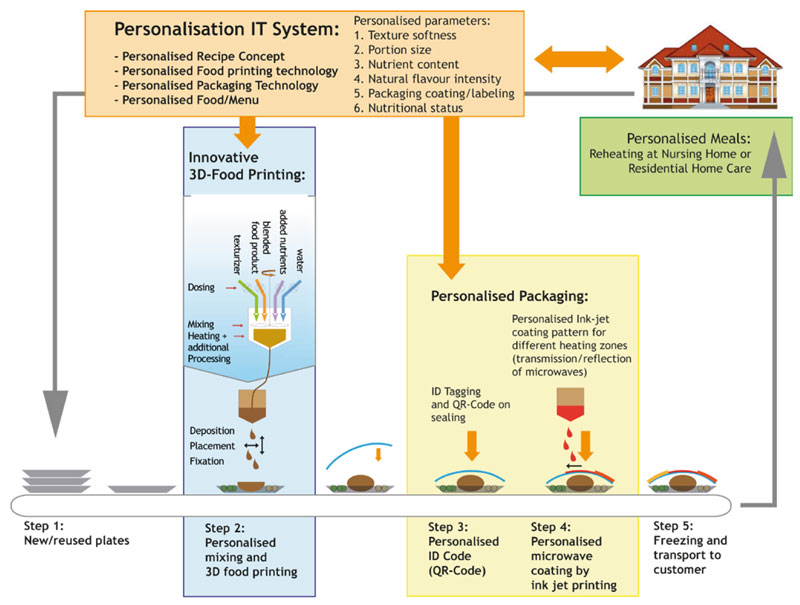

The EU project PERFORMANCE (PERsonalised FOod using Rapid MAnufacturing for the Nutrition of Elderly Con sumErs) sees 3D food printing as a key technology in a holistic and personalised supply chain that is tailored to the individual food requirements of elderly persons and persons with chewing and swallowing diffi culties (Figure 5).

Five EU Member States and 14 cooperation partners are participating in the project which is being funded with altogether three million Euro. Visually attractive preparation of the meals from the 3D printer is just as essential a project requirement as satisfying personal preferences and adapting products to individual nutrient needs. The basis for this is the Smoothfood concept in which high-value and natural foods are boiled and puréed. The puréed foods are subsequently prepared on the plate with a 3D printer. It is possible to enrich them with vitamins, mineral substances and trace elements, as well as to adapt portion sizes, textures or special diet forms individually. The costs per plate cannot yet be quantifi ed specifi cally at present, but the concept will probably not be cost-effi cient for implementation in individual institutions. The PERFORMANCE project is therefore designed for production and delivery by a central and regional enterprise.

3D Systems is one of the best-known competitors in the 3D printing industry. In January 2014 the fi rm announced a partnership with The Hershey Company, one of the world’s largest chocolate manufacturers. Their joint goal in future is to develop and realise innovative ideas in the fi eld of 3D food printing. That same year a chocolate printer, the CocoJet, was presented and this has since been used in Hershey’s Chocolate World to print individual chocolate forms for visitors on request. The ChefJet and the ChefJet Pro are further developments by 3D Systems. In October 2015 the company opened an innovative experimental kitchen in Los Angeles, the Culinary Lab. Chefs and barkeepers can already gather initial experience with the ChefJet Pro there. The culinary innovation centre will also offer events, symposia and workshops on 3D food printing in order to enable experience sharing and to drive further development.

Wegrzyn et al. (2012) see a concept for the future above all in personalised diets. The focus is on producing foods on the basis of individual dietary requirements. 3D food printing will in future account for a substantial share of personalised diet development and production for Lipson & Kurman (2014, p. 154 f.) too. The authors see a further target group in the followers of the Quantified-Self movement – people who are interested in their own biometric data. Technical aids such as fitness bracelets and associated apps record the data and assist in evaluation. With continuous tracking it is possible to observe one’s own health status and a large number of biometric data can already surveyed today. Starting from advancing development in this field, 3D food printers would in future be able to determine the nutrient requirements of an individual automatically and print the next ideal meal. Both the EU PERFORMANCE project and current research work by Lipton et al. (2015) make it clear just how interesting and relevant this topic is.

Chances and risks in future

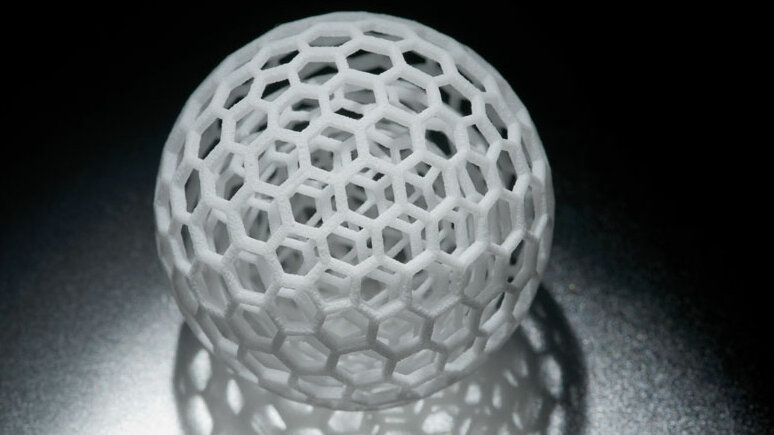

The examples listed from food practice show the possible potential of 3D food printing. Essential advantages over traditional production methods can be transferred from industrial 3D printing to the food production sector. Geometrical freedom of design is one of the aspects that is mentioned most frequently (Figure 6).

While traditional production methods often fail due to the complexity of an object to be printed, 3D printers on the other hand know no difference between simple and complex forms and require only a single work step for the printing process. Furthermore, 3D printers are able to print any form at all.

No tool changing or machine changing is involved and nor is it necessary to produce a new casting mould for a new product. Accordingly, all that 3D printing needs is a digital 3D model that can be repeatedly adapted on the computer. The Timberland Company, producer of outdoor requirements, was able for instance to reduce its costs for new prototypes from US Dollar 1,200 to US Dollar 35 and to cut production time from one week to 90 minutes (3D Systems, 2012).

Campbell et al. (2011) expect an innovation thrust from designers, engineers and hobbyists being able to realise their own and new ideas more simply and more quickly with the aid of 3D printing technology. In this connection Rayna & Striukova (2016) assume that launching products on the market will be simplified. For start-ups and entrepreneurs in the starting phase, typical problems are high expenditures for materials, machinery and premises coupled with small production quantities at the start. New business ideas based on 3D printing or 3D food printing might be able to help solve this problem.

Especially in the case of small production quantities and individual products, 3D printing has a crucial advantage over conventional production methods as regards production costs. As already mentioned, 3D printers can print any form. By contrast, in certain cases conventional production methods are either too costly or simply not possible. A further factor here is the cost involved, which would lead to production not being cost-effective in the case of small quantities and increasing complexity. Lipton et al. (2015) see a trend above all in this “smallscale food production” that can contribute to further development of 3D food printing. Bakeries, confectioners and restaurants will profit from the geometrical design freedom and in this way can create additional value for Figure 6: Complex forms from sugar with the ChefJet Pro Source: www.3dsystems.com 8 DLG Expert report 4/2017 their products. However, new opportunities with innovative products and brands that attract the attention of potential consumers and win them over for the product, the brand and the company will result for companies in the food industry as well.

The advantages of 3D printing technology are also coupled with a few disadvantages. On the basis of the examples already mentioned, it becomes clear that at the present time 3D food printing is not relevant for mass production. Furthermore, there is a trade-off between production time and printing quality. However, it is also questionable whether in future 3D food printing can and should fundamentally develop further as an alternative technology in mass production. On the other hand, depending on the production quantity, the strategic production concept of mass customization represents a realisable approach.

The composition of foodstuffs as regards their chemical and physical properties and the differences in temperature resistance and stability also make it clear that not all foods are suitable for 3D food printing. One major challenge consists in further processing steps such as cooking, frying and baking. Foods created with the 3D food printer must also retain their shape and appearance in the further processing operation. Cohen et al. (2009) see the selection of suitable foodstuffs to be the “bottleneck” in the whole constellation of 3D food printing.

A risk that should not be underestimated lies in potential copyright infringement in the dissemination of digital 3D models via the internet. The Kinderriegel chocolate bar by Ferrero or the Goldhase chocolate bunny by Lindt are examples here – both products could easily be scanned or modelled and then printed as optically exact replicas and used for the desired purposes. Campbell et al. (2011) assume that designers, engineers and lawyers will have to deal more frequently and intensively with copyright in the coming years. Sissons & Thompson (2012) can even imagine reservations of companies when it comes to investment in product research as long as there are no clear legal regulations guaranteeing sufficient protection against imitators. Admittedly there are already valid rules and laws, but it is not clear whether these are sufficient to cover all possibilities of a new technology such as 3D food printing.

Acceptance and use from the consumer perspective

3D food printing is one of the frequently mentioned food trends of the future (Nestlé Zukunftsforum, 2015; Rützler & Reiter, 2015). The prerequisite in this connection is of course consumer acceptance of the new technology. A representative study conducted in the year 2015 shows that 24 per cent of the 16 to 24 age group and 23 per cent of the 25 to 34 age group would prepare a meal with the aid of a 3D food printer (Reichelt Elektronik, 2015). However, not much more about consumer attitudes is known yet.

A qualitative analysis of the acceptance and use of 3D food printing from the point of view of consumers was conducted in 2016 within the context of a thesis for a Master’s Degree at the Justus-Liebig University in Giessen (Chair of Food Sciences). The methodological approach and the most important results are outlined briefly here.

13 individuals between the ages of 24 and 63, with an average age of 32, took part in guideline-supported interviews. Nine of the 13 participants had a grounding in food science resulting from their current or past academic background. The essential requirement for taking part in the discussion was enjoyment of cooking or baking. The idea behind this was based on the assumption that initially the consumers who would be interested in 3D food printing would enjoy processing or creative preparation of foods. At the present time it is not yet possible to assume general understanding or knowledge of foods from the 3D printer. For the guideline-supported interviews it was thus necessary to create a comparable knowledge basis. A few days before the interview the participants therefore received an email with three videos showing different possible uses of 3D food printers. Furthermore, following the interview the participants took part in a sensory assessment of a fruit gum printed by 3D (Figure 7) and also answered further questions in this connection.

One group of 32 students working for a Master’s Degree, chiefly in the fields of nutritional sciences and food economics, also participated in a written survey oriented to the guideline-supported interviews, the results of which thus flowed additionally into the qualitative analysis. The group had also participated in the sensory analysis prior to answering the questions so that in this way they would acquire understanding of 3D food printing. Given the small scope of the sample, the statements by the interviewees and the group of students are only representative to a limited extent, but they provide a good first impression from the perspective of potential consumers.

The interviewees had difficulty in imagining the use of a 3D food printer in private households at the present time. High purchase prices and a lack of individual added value are the essential reasons for this. According to Perrea et al. (2015), a disproportionately high price can have a negative effect on the benefit perceived. The technology would be interesting for the participants, but above all for the creation of personal gifts, personalised greetings, or decoration of cupcakes, cakes or tarts. Playful preparation of healthy food for children, such as fruit and vegetable purées in the form of animal figures, is also conceivable. Procurement and follow-on costs, hygiene and cleaning possibilities, as well as the quality of the printed results are key factors in a potential decision to buy. At the same time hygiene and cleaning opportunities as well as the quality of the printed products are felt to be possible problems in use. From the perspective of the participants, operation should be intuitive in order to facilitate the first steps in 3D food printing and ensure optimal printing results. However, there were only few reservations regarding the technology or the printed foods. Yet pre-fabricated products from the trade are viewed more critically than self-prepared foods for filling the 3D printer.

A small scenario was developed for the thematic questions on use in the restaurant industry – ordering a chocolate dessert from the 3D printer in a restaurant. The interviewees showed a high level of acceptance for a 3D-printed dessert made of chocolate and would accept a relatively long waiting time after ordering. However, the low willingness to pay for a 3D-printed dessert despite the fact that this is an innovative approach to food preparation is striking. The participants readily confirm the added value as reflected in the experience. One explanation possibly lies in the nature of the group being questioned – students have less available income and therefore may display greater sensitivity to prices. The idea of bringing one’s own 3D model on a USB stick or mailing it to the restaurant in advance received very positive reactions. Suitable opportunities for this are for instance special occasions such as birthdays, weddings or company celebrations.

From the point of view of the participants, 3D food printers will still not be widespread in private households ten years from now. Product demonstrations in supermarkets, low procurement and follow-on costs, a high range of functions and added value by facilitating work are among the factors named as essential measures and criteria for driving dissemination. With classic product demonstrations at the point of sale, the food retail trade would also be in a position to expand its own range of goods and services and produce individual products directly or on order for customers. Individual branches could sharpen their profile against local competitors with strategic activities of this kind.

Concluding remarks

This overview has shown that good results can already be achieved with 3D food printing, with a range of different foods too. There appears to be no limit to the ideas for potential applications. At the same time, the technology will produce chances not only for large-scale companies, but above all for entrepreneurs and start-ups as well that can benefit from easier market access. Furthermore, initial studies show acceptance and openness of consumers for the new technology. Despite this, 3D food printing still has a long way to go before it reaches the famous replicator from Star Trek, which repeatedly serves as an example in this connection.

Reference list:

- 3D Systems (2012): The Timberland Company: Timberland Saves Time and Money, Finds the Right Style with 3D Printing. Available at: 3dsystems.com/sites/www.3dsystems.com/files/21_CaseStudy-Timberland- FINAL.pdf [28.02.2017].

- Campbell, T., Williams, C., Ivanova, O. und Garrett, B. (2011): Could 3D Printing Change the World? Technologies, Potential, and Implications of Additive Manufacturing. Available at: atlanticcouncil.org/images/files/publication_pdfs/403/101711_ACUS_3DPrinting.PDF [28.02.2017].

- Cohen, D.L., Lipton, J.I., Cutler, M., Coulter, D., Vesco, A. und Lipson, H. (2009): Hydrocolloid Printing: A Novel Platform for Customized Food Production, in Bourell, D.L., Crawford, R.H., Seepersad, C.C., Beaman, J.J. und Marcus, H. (Eds.): Solid Freeform Fabrication Proceedings. 20th Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference. University of Texas at Austin, Austin, Texas, 3.–5. August, p. 807–818. Available at: sffsymposium.engr.utexas.edu/Manuscripts/2009/2009-71-Cohen.pdf [28.02.2017].

- Cotteleer, M., Holdowsky, J., Mahto und Monika (2014): The 3D opportunity primer: The basics of additive manufacturing. Available at: dupress.deloitte.com/content/dam/dup-us-en/articles/the-3d-opportunity-primer-the-basics- of-additive-manufacturing/DUP_718-Additive-Manufacturing-Overview_MASTER1.pdf [28.02.2017].

- Forstner, S. & Rusu, A. (2015): Development of personalised food for the nutrition of elderly consumers, in Dumitras, D.E., Jitea, I.M. und Aerts, S. (Eds.): Know your food: Food ethics and innovation. Wageningen: Wageningen Academic Publishers, p. 24–27.

- Godoi, F.C., Prakash, S. und Bhandari, B.R. (2016): 3d printing technologies applied for food design: Status and prospects. Journal of Food Engineering, 179(June), p. 44–54.

- Gong, J., Shitara, M., Serizawa, R., Makino, M., Kabir, M.H. und Furukawa, H. (2014): 3D Printing of Meso-Decorated Gels and Foods. Materials Science Forum, 783-786(May), p. 1250–1254.

- Jia, F., Wang, X., Mustafee, N. und Hao, L. (2016): Investigating the feasibility of supply chain-centric business models in 3D chocolate printing: A simulation study. Technological Forecasting and Social Change, 102(January), p. 202–213.

- Lipson, H. & Kurman, M. (2014): Die neue Welt des 3D-Drucks, Weinheim: Wiley.

- Lipton, J.I., Cutler, M., Nigl, F., Cohen, D. und Lipson, H. (2015): Additive manufacturing for the food industry. Trends in Food Science & Technology, 43(1), p. 114–123.

- Lipton, J.I., Arnold, D., Nigl, F., Lopez, N., Cohen, D., Norén, N. und Lipson, H. (2010): Multi-Material Food Printing with Complex Internal Structure Suitable for Conventional Post-Processing, in Bourell, D.L., Crawford, R.H., Seepersad, C.C., Beaman, J.J. und Marcus, H. (Ed.) Solid Freeform Fabrication Proceedings. 21st Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference. University of Texas at Austin, Austin, Texas, 9–11 August, p. 809–815. Available at: sffsymposium.engr.utexas.edu/Manuscripts/2010/2010-68-Lipton.pdf [28.02.2017].

- Nestlé Zukunftsforum (2015): Wie is(s)t Deutschland 2030? Nestlé Zukunftsstudie, Frankfurt am Main: Deutscher Fachverlag.

- Periard, D., Schaal, Noy, Schaal, Maor, Malone, E. und Lipson, H. (2007): Printing Food, in Bourell, D.L., Crawford, R.H., Seepersad, C.C., Beaman, J.J. und Marcus, H. (Ed.): Solid Freeform Fabrication Proceedings. 18th Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference. University of Texas at Austin, Austin, Texas, 6–8 August, p. 564–574. Available at: sffsymposium.engr.utexas.edu/Manuscripts/2007/2007-48-Periard.pdf [28.02.2017].

- Perrea, T., Grunert, K.G. und Krystallis, A. (2015): Consumer Value perceptions of food products from emerging processing technologies: A cross-cultural exploration. Food Quality and Preference, 39(January), p. 95–108.

- Rayna, T. & Striukova, L. (2016): From rapid prototyping to home fabrication: How 3D printing is changing business model innovation. Technological Forecasting and Social Change, 102(January), p. 214–224.

- Reichelt Elektronik (2015): Zwei Drittel der Deutschen wollen 3D-Drucker nutzen. Press release, 22 May. Available at: presseportal.de/pm/115736/3028785 [28.02.2017].

- Rützler, H. & Reiter, W. (2015): Food Report 2016, Frankfurt: Zukunftsinstitut.

- Sissons, A. & Thompson, S. (2012): Three Dimensional Policy: Why Britain needs a policy framework for 3D printing. Available at: nibec.ulster.ac.uk/uploads/documents/3d_printing_paper_final_15_oct.pdf [28.02.2017].

- Soares, S. & Forkes, A. (2014): Insects Au Gratin – An Investigation into the Experiences of Developing a 3D Printer that uses Insect Protein Based Flour as a Building Medium for the Production of Sustainable Food, in Bohemia, E., Eger, A., Eggink, W., Kovacevic, A., Parkinson, B. und Wits, W. (Ed.): Proceedings of the 16th International Conference on Engineering and Product Design Education. 16th International Conference on Engineering and Product Design Education. London South Bank University, Enschede, Netherlands, 4–5 September. Glasgow: The Design Society, p. 426–431.

- Southerland, D., Walters, P. und Huson, D. (2011): Edible 3D Printing, in Society for Imaging Science and Technology (Ed.) Conference Proceeding. NIP 27: International Conference on Digital Printing Technologies and Digital Fabrication. Society for Imaging Science and Technology, Minneapolis, Minnesota, 2–6 October, p. 819–822. Available at: imaging.org/site/PDFS/Reporter/Articles/REP26_5_6_NIP27DF11_SOUTHERLAND_PG819.pdf [28.02.2017].

- Wegrzyn, T.F., Golding, M. und Archer, R.H. (2012): Food Layered Manufacture: A new process for constructing solid foods. Trends in Food Science & Technology, 27(2), p. 66–72.

Contact:

Dr. Annette Schmelzle, DLG Competence Center Food, A.Schmelzle@DLG.org